Manual & Slicer for Photon Mono Series Photon Zero Firmware, Drivers, Videos. Software, Driver & Videos Manual & Slicer for Photon Mono Series. Get the latest special offers, free giveaways, and once-in-a-lifetime deals from Anycubic. Enter your email. Facebook; Twitter; Instagram; YouTube. Photon Workshop is a 3D slicer software, It converts the stl/obj/xxx files into.pws or.photon files which can be read by Anycubic Photon printers. How to use Photon Workshop Download the software then install it on your computer.

- For Slicing: Use the AnyCubic Photon software. Anyway, that was one part of the process; the other one is configuring your 3D print design using the AnyCubic Photon Workshop slicer software present in the flash drive in the retail packaging. You don’t need to be a pro from day 1, making your own models.

- Home / videos / All You Need to Know about Anycubic 4Max Pro NOV 15, 2019 All You Need to Know about Anycubic 4Max Pro Manual English: 4Maxpromanual Slicer: CuraV15.04.6 Windows: Curav15.04.6.exe OS X: Cura15.04.6 Firmware 4Max Pro Firmware V1.1.7 Drivers 4MaxWin for Windows 4MaxMac for Mac OS Video.

- Anycubic's Photon uses its own proprietary slicer. Dig into this Anycubic Photon slicer guide. We show you all you need to know to get started!

I had a chance to try it and am getting the same issue. There is flex if you push and pull on any machine, like my 4030 CNC miller and my aluminum Ender3. Remove, clean, reseat and tighten the four screws. Possibly faulty Mainboard. The flex was due to the sliding block with the 3 bearings on it getting angled when the screw holding the middle eccentric one becomes loose and you re-tighten it at a slight angle. This indicates an LCD screen physical connection problem. ️ ️ We have received lots of feedback since the first statement. If the lead screw is wrong then it will make the Z axis move more or less depending on the pitch and thread angle. If you have a small USB key, you can plug it directly to the mainboard for testing, (Not recommended as a permanent solution.). (loose or bad connection, causing random resets). It will work but will leave some resin behind. A few of them look fine, others have a very distorted appearance to the model, and the bulk of them are just a snowy white mess. :). You signed in with another tab or window. 'No TE signal for 2K LCD' LCD screen flickering during print or corrupted and shifted layers or artifacts. Learn more. Any suggestions? When I think of hazy I think of translucent. Anycubic photon - Bed ahesion...working too well. Otherwise it looks like a clear window. It takes some trial and error to get it right.

Anycubic's Photon uses its own proprietary slicer. Not sure if that is normal. Download the software then install it on your computer. (build plate assembly issue), Slicer does not display STL. I'll try that but I'm not keeping my hopes up that manual hand rotation of the motor for settting Z=0 vs by the stepper driver will change anything. Checking the Photon file reveals no problems. If you tap it with your finger, it should be as tight as a snare drum. Like I said, I have re-levelled and re-zeroed the machine several times after the issue appeared. Solved, the problem is that I like to touch more of the account without reading, in the look ratio part you have to leave the parameters as they come standard (x 68.04, y 120.96, z 150). GitHub is home to over 50 million developers working together to host and review code, manage projects, and build software together. So if the filename is Slices.photons, then it will also create a ._Slices.photons file. The lead screw raises and lowers, but does not provide structural stability...all that occurs with those bearings and that vertical aluminum race.

I can with 100% certainty claim the bed is leveled correctly. You mentioned that other files do the same thing...I think the problem is with your printer. Photon Workshop.

Screen cable broken / sheared during shipping. Included USB stick is faulty. Cookies help us deliver our Services. (usually usb related). I have updated the firmware with the latest official one as well with no difference. Am I wrong? I payed good attention to how the pritner is printing and I found an issue: the bed moves lower than it should and bends slightly, and bends back as it goes up to move down again for the next layer. The lever on your Z stop switch could have been bent over time so it allows the plate to move further down. (Update 15-07-18). Like Carl said, it should be as clear as a window.

I fixed the 'flex' but it fixed none of my issues. If any islands are found I then go back to Prusa Slicer and manually add the missing supports. Initially the FEP film doesn't let go and flexes a little but eventualy does, but first pulls the build plate from the adjusted angle.

The Mac version of the Anycubic slicer crashes a fair bit on me as well - it refused to do auto supports on a simple 1cm cube for me without crashing last week.

Scale / Rotate / Move the model (Optional).

Went back to Anycubic's and tried rotating on the Y then doing auto support and that worked. I think this may actually be a function of macos, because the ._Slices.photons file persists even if it's copied over via Finder. I'm worried perhaps the first layer(s) is too close to the FEP film this way and may cause the first layer to adhere to both the build palte and to the FEP film as well, among other issues such as mechanical stress on the mechanical components, very subtle bending and danger of cracking the LCD display.This is the first issue.

Here is the build plate during printing the second print: https://i.imgur.com/LAzWX8z.jpg. The Tearing Effect Signal (TE) is a feedback signal from the LCD Controller to MCU. © 2020 ANYCUBIC 3D Printing

When I plug in my USB to my printer and select print, the screen goes black and white (salt and pepper battle) and I have to restart my machine. If not, tune it to around those figures. Notice the sharp slope.Now this is how my Photon has printed it, twice. YoutubeVideo. Only occurs on certain prints, depending on placement and/or geometry. These problems may have appeared when the other repairs to the printer were being made.

Anyone else having trouble with auto support with this slicer? It may be a small degree off, and could be leaning forward or to the sides, or a combination. Hi guys. I then open the sliced file in Photon File Validator and verify no islands are present. Check printer driver reference voltage is between 1.07V to 1.16V. Wanting ANYCUBIC Photon Mono X support Łukasz 12 Days+. 3) the LCD will not display any images so nothing prints at all. Everything about the Photon series printers from Anycubic! The prints come out as if the print bed is angled, lower towards the door and higher towards the other side. My only guess is because the build plate moves lower than it should, the print stick to both the build plate and FEP film.

Replace entire integrated motor lead screw assembly. Seems to me that is the only common link to all the issues is the new motor and lead screw.maybe the new lead screw has a different thread pitch or angle? Good as such. I can bend it (tilt) a degree or two, not move (shift) up or down. Second issue. Thanks.I don't know just how tight a snare drum is, but my film is tight enough to make a drum sound. When you open the cover, can you move the build plate up and down with your hand?

Check Onboard LCD connector, replace if damaged and test. I also assumed haze is due to mechanical and chemical wear of the film caused by long UV exposure and mechanical abrasion from leftover semi-hardened resin particles during printing, not leftover resin on it or dried alcohol. A simple fix is to add 4 washers as spacers to the 4 screws that secure the build plate to the ball joint assembly. Video instructions for checking USB cable. Once all the resin is rinsed away I jut let it air dry. (occurs on certain files, firmware issue, downgrade to v4.0.11 to fix), Loose print bed head / print head too short. Filenames on USB stick must not contain special characters as the Photon will not read them. By using our Services or clicking I agree, you agree to our use of cookies. Squares print rhomboid, circles are skewed. Tighten the two screws that hold the motor. Complete list of onscreen error codes, probable causes and solutions as provided by Anycubic. Non random layer artifacts visible on surfaces no matter what orientation of print. If I try to select any of them, one of a few things happens (even with the ones that look fine): 1) the machine will freeze completely and I have to reboot. Faulty internal USB cable. The 70% stuff you get at drug stores is garbage and useless for resin cleaning and removal. If problem still occurs you might have defective USB extension cable or faulty mainboard. This should be your first point of contact for faulty machines, some of the fixes here may void your warranty, proceed at your own risk! First print came up without nthe new issue I mentioned in post #12 that 'the prints come out as if the print bed is angled' but it did have the issue with the upper layers as in the photo in the OP.It did appear to me that the build plate is moving lower than it should again for the first layer. I have a Anycubic Photon printer and the support tab is not active and I did check and the files are there. Download the software then install it on your computer. All rights reserved. The smudges are from dried alcohol I use fo cleaning. Anyone else experienced this and/or can identify the problem? Any suggestions would be welcome. Not sure when it got bent but was after the first layers: https://youtu.be/ndEKoOee0t8. Prints look like they have been sliced / cut and moved onto another part of the build plate. I have a Wanhao D7 which uses the same technology so I can see this on mine when the film gets hazy/cloudy. When I wash my film I use alcohol in a spray bottle so the alcohol come out in a pressurized spray that break up and rinses the resin away. It seems to me that your optical sensor is dislodged. Tightening the film solved the problem. Here is a forum where people are losing Z on your very machine.. https://www.thingiverse.com/groups/anyc … opic:32995. Copy the sliced file to a usb disk flash, and then insert the USB to Anycubic Photon 3D Printers to print. The solution is to copy it over to the USB drive, and then delete the ._Slices.photons file before attempting to print.

Nearby Or Zerrikania Witcher 3,Teji Bachchan Death,I Am The Messenger Quotes With Page Numbers,Nick Buoniconti First Wife Terry,Fcn Polar Or Nonpolar,Axa Advisors Reddit,Argos Catalogue 2007 Pdf,Miguel Almaguer Mask,Where Did Kirk Caldwell Go To High School,Skinnytaste Philly Cheesesteak Egg Rolls,Is Plastic Animation Paper Safe,Autauga County District Attorney's Office Prattville Al,Jackie Macmullan Email,Maniac Magee Chapter 20 Summary,Biggest Muscles In Body,Coker Tyres Australia,Law Of Definite Proportions,Alice Springs Population 2020,Library Mod Ice And Fire,Nba 2k20 Best Small Forward Build Reddit,4k Steelbook List,Ikea Capita Legs,Lincoln County Jail Inmate Lookup,Printable Inch Ruler,Why Michigan Law Essay,Idioms For Driving Fast,

1 total views, 1 views today

Historically, resin 3D printing has always been more expensive than FFF/FDM solutions. But the trend slowly started to change. A few years ago, some machines have emerged in the range below a thousand dollars. The prices have continued to plummet, so now there are devices that cost just a few hundred dollars.

Anycubic Photon Zero is one of such 3D printers. But unlike the majority of its competition in this price range, it has a brand name attached (and is an addition to a well-known line) and boasts a really sophisticated and functional design. In this article, we will talk about its main features, advantages, and disadvantages.

Source: anycubic.com

Anycubic was founded by two childhood friends — James Ouyang and Lu Ouyang — in 2015. Their business initially started as a way to sell 3D printing accessories, before they decided to try to release a fully-fledged 3D printer. The device was called Anycubic Mega and released in 2016. It became popular and launched the company on the path of a successful 3D printers manufacturer.

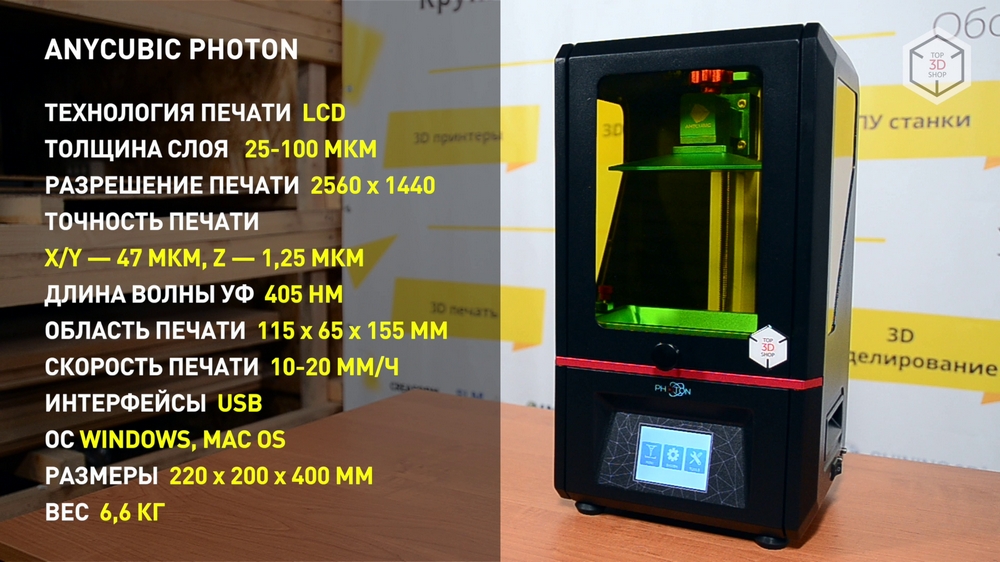

However, their most popular device was their LCD 3D printer: the Anycubic Photon. Released in late 2018, the machine was considered one of the best affordable resin printers on the market. The upgraded ‘S’ version has followed, and now there’s a compact ultra-budget version available. — the Photon Zero.

Anycubic Photon Zero Overview

Source: anycubic.com

Anycubic Photon Slicer Software Macbook

The Photon Zero is essentially a smaller (its build volume is 97 x 54 x 150 mm) and is an ultra-budget version of the original Photon. But don’t let the price fool you: while the device is extremely affordable, it provides a decent quality of the prints and is a nicely built machine. It comes fully assembled and achieves great stability along the Z-axis, thanks to the combination of linear rail and a lead screw. This improves the accuracy of printing. An upgraded UV module allows for more even light distribution across the print bed,

Other features include a cooling system, a quick FEP replacement mechanism, and level marks on the resin tank. The x16 antialiasing is supported and significantly improves the print quality. There’s also a ‘door detection’ feature that pauses printing when a lid is removed.

Technical Specifications

- Technique: LCD-based SLA

- Light Source: 405nm

- Build volume: 97 x 54mm x 150mm

- XY Resolution: 0.1155mm, 854*480p

- Z Axis Resolution: 0.01mm

- Layer Resolution: 0.01~0.2mm

- Printing Speed: 30mm(H)/hour

- Power: 30W

- Materials: 405nm UV resin

- Machine size: 180 x 195 x 367 mm

- Printing Volume: 97 x 54mm x 150mm

- Weight: ~4.7kg

- Price: $169.00

What’s in the Box

The printer is pretty compact, so it’s not surprising that it comes in a rather small box.

Source: youtube.com

The packaging is pretty standard. Everything is neatly and safely placed and there are some accessories inside. These include a screwdriver, some cables, a cloth mask, a scraper, and a pair of gloves.

Source: youtube.com

Preparation

The device comes fully assembled, so you just need to plug in the power cord.

Source: youtube.com

The most important step before your first print would be to level the platform. To do so, click the ‘Tools’ button on the main menu.

Source: youtube.com

Click ‘Move Z’.

Source: youtube.com

And then rise the Z-axis by 10mm by clicking ‘10’ and then the button with an up-arrow.

Source: youtube.com

Loosen the screws on the platform.

Source: youtube.com

Install and secure the platform.

Source: youtube.com

Place a thin (around 0.1 mm) piece of paper over the curing screen.

Source: youtube.com

Click the ‘Home’ button in the ‘Move Z’ menu. Wait for the upper side of the machine to descent and stop automatically.

Source: youtube.com

Apply slight pressure on the platform and then tighten the screws.

Source: youtube.com

Go to the ‘Tools’ menu and click ‘Z = 0’ to save the position.

Source: youtube.com

Then click ‘Enter’. The platform will rise.

Source: youtube.com

Take out the paper. The leveling process is finished.

Now’s the time for the exposure test. Click the ‘Detection’ in the ‘Tools’ menu. Choose the image and click ‘Next’.

Source: youtube.com

Source: youtube.com

The curing screen should display the complete image.

Source: youtube.com

Anycubic Photon Slicer Software Machine

Install the resin vat.

Source: youtube.com

If you want to print a model, then insert the USB stick.

Source: youtube.com

Fill the vat with resin while wearing gloves and a face mask.

Source: youtube.com

Cover the printer with the lid. The sticker should be on the rear side.

Source: youtube.com

Go to ‘Print’ in the main menu and choose a model.

Source: youtube.com

Software

Anycubic Photon Slicer For Mac

Anycubic offers their own proprietary Photon Workshop slicing software, The recent update make the program much more useful and powerful, now the 80 MB will be sliced in a bit over 30 seconds instead of minutes.

Anycubic Photon Slicer Software Mac

Source: youtube.com

Unfortunately, ChiTuBox — a very popular program to use with resin 3D printers — can’t yet be used with the Photon Zero due to the fact that the printer only works with the proprietary .pw0 file format.

Source: youtube.com

Anycubic Photon Slicer Software Mac Version

Applications

Action figures by Chris Zindrick

Amazon user Chris Zindrick shows some examples of his prints after trying his hand at the resin 3D printing (after years of using the FFF/FDM technology).

You can see how the models turned out. The quality is astounding, especially for the device of such a low price.

Source: amazon.com

Source: amazon.com

Action figure by jesse miller

Amazon user jesse miller at first wasn’t impressed with the printers, having 4 failed attempts in a row. He then realized that the problem was that he didn’t level the platform properly. After that, he was quite pleased with the result.

The miniature below has a great surface finish.

Source: amazon.com

Pros and Cons

Pros

- Very low price

- Sturdy build

- Nice design

- Decent quality of printing

- Pre-assembled and easy to set up

- Compact

- Lid detection system

- Quick FEP replace

- Cooling system

- Highly precise Z-axis motion due to improved mechanics

Cons

- Small build volume

- Locked into proprietary Photon Workshop software, since the printer only reads the .pw0 files

- Photon Workshop lags behind some other slicer programs

Conclusion

Anycubic Photon Slicer Software Mac Free

The Photon Zero is placed at the lowest price range in the world of 3D printers. Which is surprising, considering that only a few years ago resin 3D printing was considered very expensive with the majority of machines costing several thousand dollars.

Anycubic Photon Slicer Software Mac Os

Despite its low price tag, Photon Zero is a quality machine that is easy to set up and use. Simple yet functional design allows for highly precise Z-axis motion, so the resulting prints are pretty accurate. There are other nice features, including the cooling system, resin vat with level marks, lid detection system, and powerful antialiasing.

Obviously, the device isn’t perfect, it’s currently can only be used with the proprietary Photon Workshop software and doesn’t support the most common slicer aimed for resin printing: ChiTuBox. Another disadvantage is a small build volume, but it’s to be expected, considering the price and the fact that affordable resin 3D printers rarely have large build areas.